Zinc Die Casting Connector

| Product parameters | |

| Name: | Zinc Die Casting Connector |

| Model Number: | STK-Z001 |

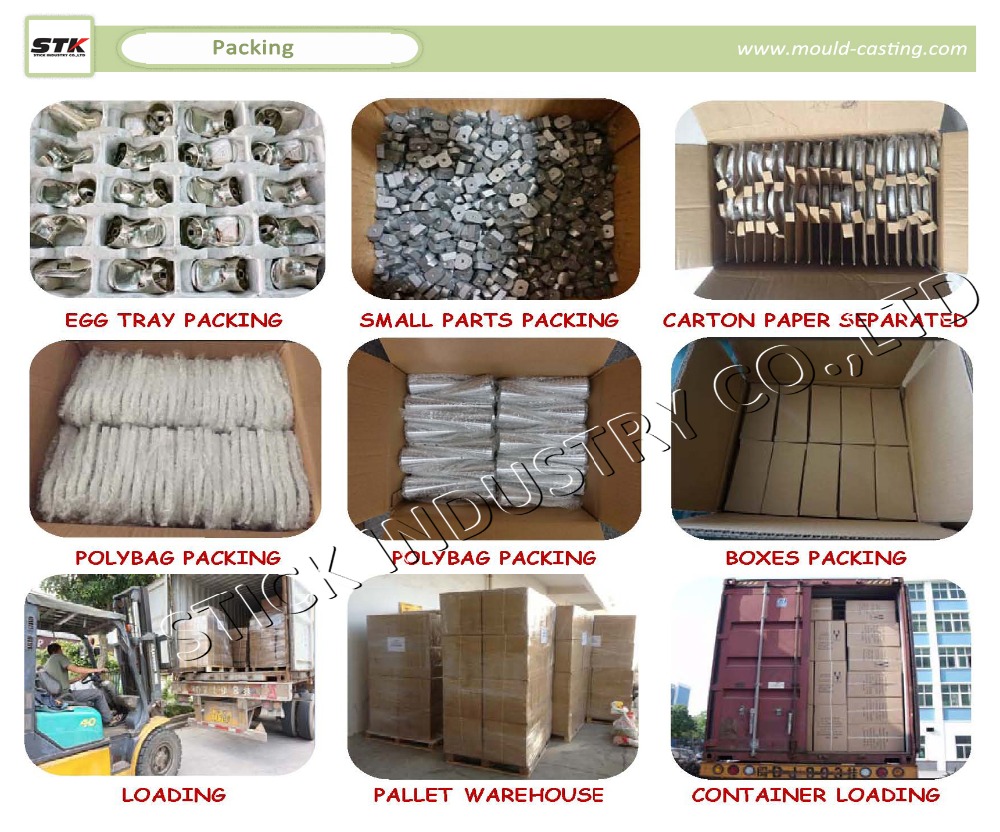

| Packing | Paper+Bubble Bag |

| Origin | Xiamen, China |

| Payment Terms | L/C, T/T, Western Union |

| Minimum Order | 500 Pieces |

| Delivery Time | 20-30 days |

| Contact Us | |

Tel:86-592-5811670E-mail:anna@stickindustry.com

|

|

|

|

Product Description

Specific Zinc Die Casting Capabilities

Automated equipment handles high volume casting jobs of up to 100,000 pieces per week

Manual machines for low volume jobs of minimum quantity of 500 pieces per year.

Can cast from 0.02KGS to 5KGS

Single to multiple cavities

6 sets of hot chamber die casting machines range from 88Tons to 280Tons.

Most zinc casting alloys are offered such as Zamak2, Zamak3, Zamak5, Zamak7, ZA8, ZA27 etc.

Specializing in small, large, complex, precision components

Item Name: | Zinc Die Casting Connector |

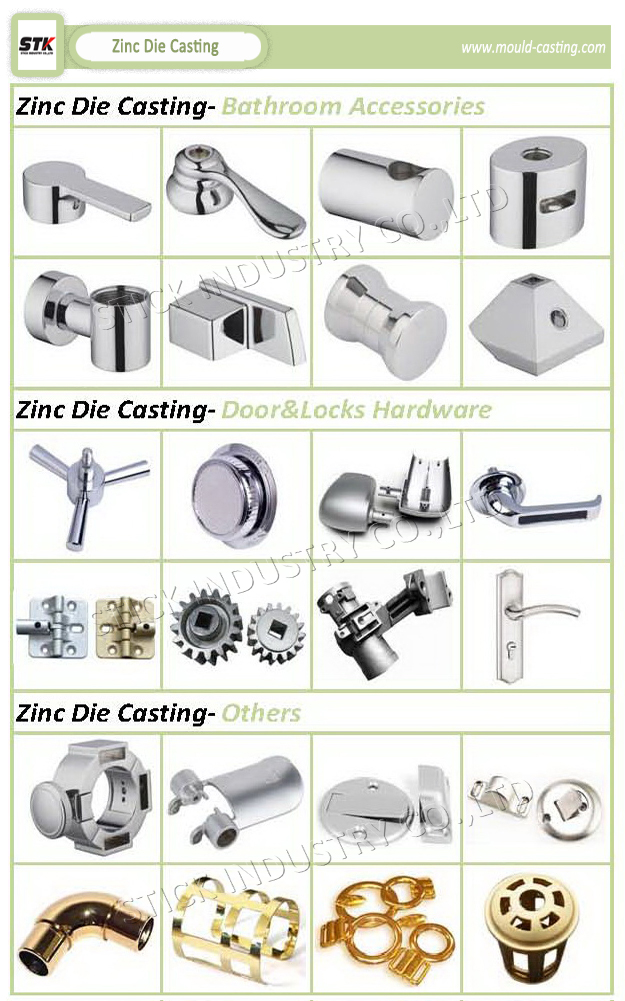

Product Description: | 1) Material: Zamak 3, Zamak 4, Zamak 5, Zamak 12 etc. 5)Product scope: Auto parts, motor shell, pump parts, machinery parts, electronic parts, medical parts, furniture accessory etc. |

Company Profile: | With plentiful experience and skillful technique, Xiamen Stick Industry Co., Ltd produce the best quality zinc die casting and aluminum die casting as per our customer’ s drawing or sample.The picture shown is the customized product we make for our customer, for reference only. Any OEM service is welcomed. |

Company advantage: | 1. ISO 9001: 2000 certified |

Manufacture Process: | 1) Die Casting reaming and threading |

| EQUIPMENT LIST | CAPACITY | QTY |

| HOT CHAMBER DIE CASTING MACHINE | 88 TONS | 2 SETS |

| HOT CHAMBER DIE CASTING MACHINE | 160 TONS | 2 SETS |

| HOT CHAMBER DIE CASTING MACHINE | 200 TONS | 1 SET |

| HOT CHAMBER DIE CASTING MACHINE | 280 TONS | 1 SET |

| CNC LATHE MACHINE | 10 SETS | |

| MILLING MACHINE | 8 SETS | |

| DRILLING MACHINE | 20 SETS | |

| TAPPING MACHINE | 10 SETS | |

| VIBRATE POLISH MACHINE | 3 SETS | |

| SAND BLASTING MACHINE | 1 SET | |

| POLISHING MACHINE | 30 SETS | |

| CHROME PLATING LINE | NICKLE,CHROME(MATT/BRIGHT) | 3 LINES |

-

News

- Stick Industry is taking video to show our up-to-date production capacity

- Industrial Exhibition in Germany--HANNOVER MESSE 2016

- STK will participate in 2016 HANNOVER MESSA

- STK organized trip to Europe for celebration of 11th anniversary

- STK at RosMould 2014 in Moscow

- Advantages of Zinc Alloy Die Casting

- How to inject ABS material

- Polypropylene (PP)

-

FAQs

- Q. What measures taken up when you receive customersŌĆÖ complaints on quality issue?

- Q.Do you have any 3rd party Trade Assurance?

- Q.How to Weld Aluminum Die Casting?

- Q.What is Rapid Prototyping?

- Q.What are Zinc Die Casting Parts?

- Q.What is Die Cast Molding?

- Q,How to get us accurate quotation?

- Q. What is Die Casting?

Xiamen Stick Industry Co., Ltd.

Address: Unit05C’╝īHaifu Business Center A,#597 Sishui Road, Xiamen,ChiZip: 361008

Telephone: 86-592-5811670

Mobile Phone: 8613860138705

Fax: 86-592-5209672

E-mail:anna@stickindustry.com